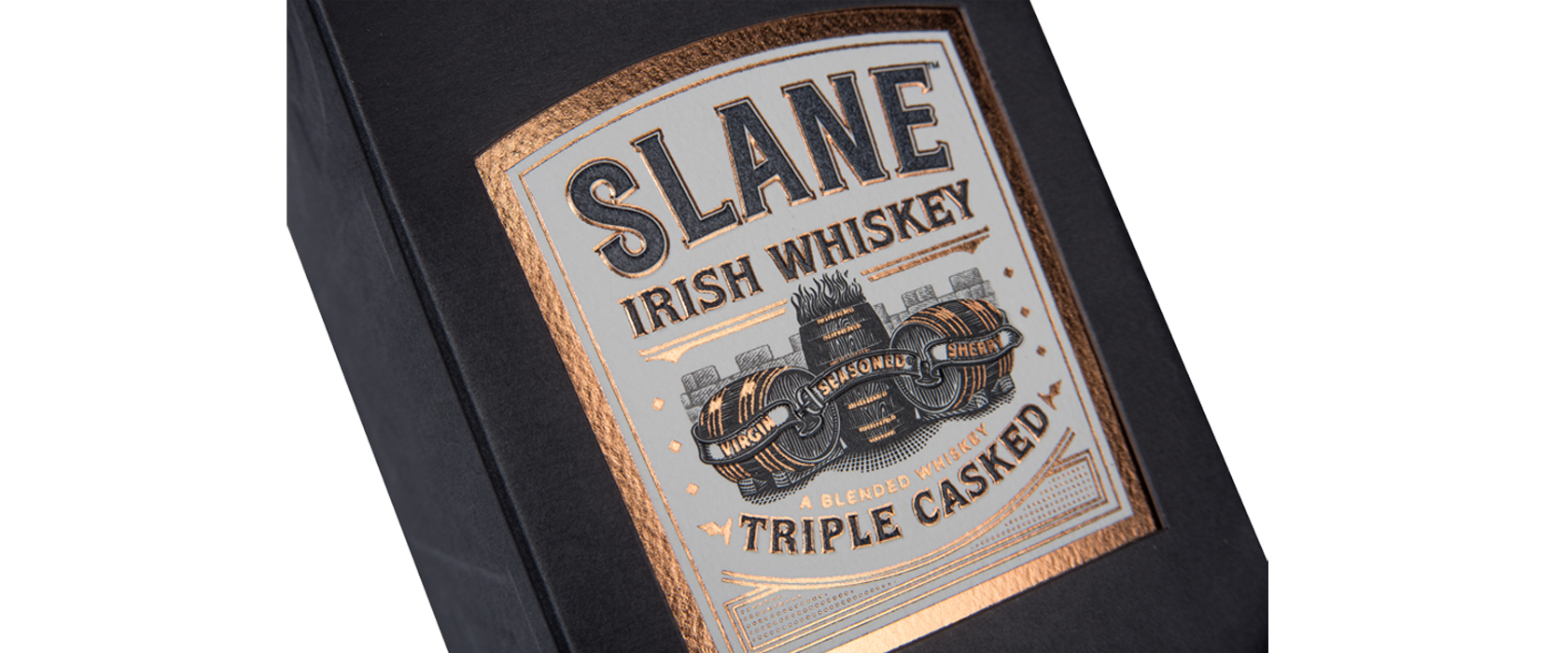

Also known as hot stamping – is done by applying pigment or metallic foil to paper using a hot die. The heated die presses the foil onto the surface, and the design of the die is then stamped onto the paper. The types of foils that can be used for the foil stamping process are metallic foils, gloss or matte pigment foils, special effects foils, and holographic foils.

Alters the surface of paper stock or other substrates by providing a three-dimensional or raised effect on selected areas. The procedure requires the use of two dies: one that is raised and one that is recessed. The dies fit into each other so that when the paper is pressed between them, the raised die forces the stock into the recessed die and creates the embossed impression.

Is similar to embossing, but recesses the design rather than raising it. Rather than the paper being raised in specific areas, it is indented. The process involves applying pressure to the front side of a substrate and forcing the material down from the surface.

Is a departure from the ordinary. It is a coating that, when applied, creates a velvety texture. The paperboard becomes “soft” to the touch and increases the tactile appeal. Soft Touch® coating creates a softer look and feel on printed materials than either aqueous or UV coating, while creating a barrier which is fingerprint resistant. Darker color palettes will appear more muted and sophisticated.

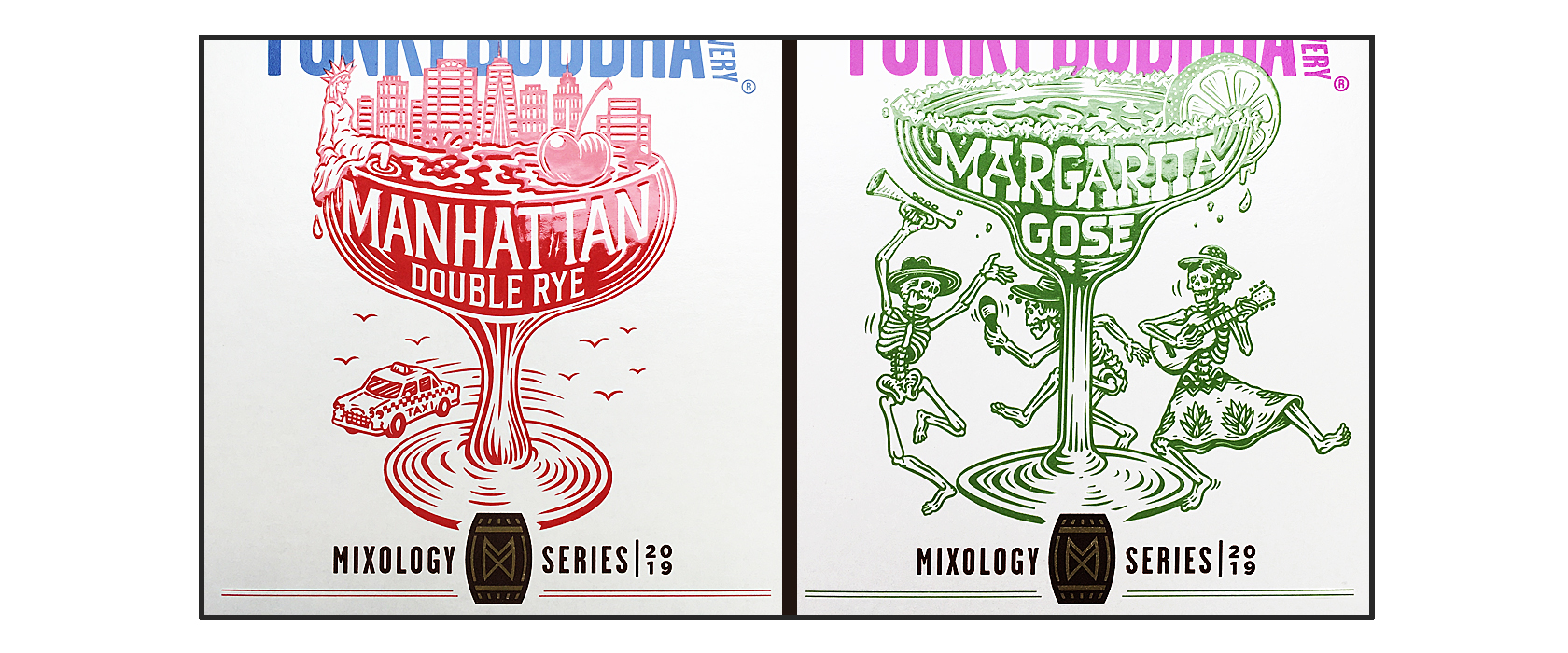

Due to its eye catching appearance and versatile applications, Spot UV is one of the most popular printing techniques available. While all UV coatings protect the paper they cover, spot UV is mainly used for its decorative effect as light catches the partially coated portion of the paper. You can achieve a dramatic effect when used in combination over matte/dull varnish, foil and embossing techniques.

Rotary screen effect UV coating cures to a raised, clear surface with a high gloss finish and smooth tactile feel. Designed to use with a 200-line mesh, using a lower count mesh will increase the amount of raised surface. Suited for high end folding cartons and prime labels that require an unusual effect.

Today’s brand marketers and packaging designers have many coating options to choose from including but not limited to: